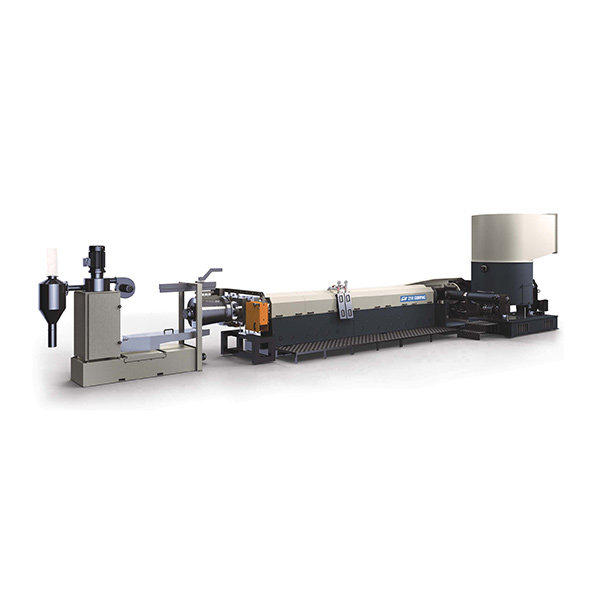

Tandem Systems

Designed to Recycle Heavily Printed, Humid, and Contaminated Materials

The Tandem System employs Gamma Meccanica’s COMPAC feeding unit and, as the name suggests, two extruders arranged in tandem. The short, non-vented primary extruder and the larger diameter secondary extruder allow for a reduction of the cutting forces and put less stress on the melted material.

Between the two extruders is a high-performance degassing chamber that provides 10 times more exposure to vacuum than a standard extruder. This guarantees the extraction of large quantities of gas and contaminants, making it highly effective to recycle heavily printed thermoplastic materials.

In addition, the Tandem line allows for double filtration. One filtration unit can offer coarse filtration, while the other can allow for finer filtering ensuring higher quality granules.

TANDEM PLUS SYSTEM

THE ULTIMATE UPCYCLING SOLUTION TO ADD HIGHER VALUE TO WASTE MATERIALS

The TANDEM PLUS line has all the advantages of the classic TANDEM plus the possibility to improve the characteristics of material during the upcycling process. This solution is ideal for the production of compounds for special applications. This Tandem model provides the combination of the first extruder as a single screw and the second a twin screw. The polymer is “enriched” with master, calcium carbonate, and various additives inside the twin-screw extruder.

Would you like more information on the

Tandem System?

We’re here to help.

Fill out the form below and our team will contact you soon.