COMPAC System

Superior Efficiency, Productivity, and Energy Savings

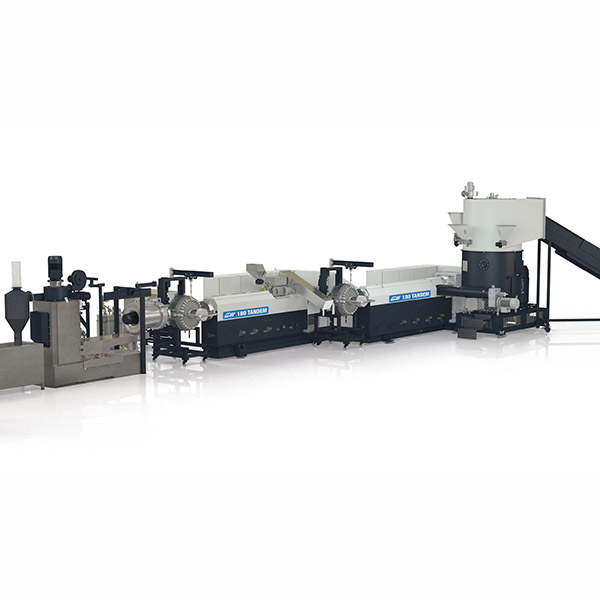

The COMPAC System represents the most advanced technology on the market. It is specifically designed for ultimate flexibility and equipped to deal with specialized materials including rigids, films, sheet, nonwovens, fabrics, and yarns. The system is typically composed of:

- Conveyor Belt with metal detector

- Cutter-compactor

- Extruder

- Filter

- Underwater pelletizer TI or water ring pelletizer TDA

- Panel with touchscreen

This type of line is available in different models depending on the production capacity. Every line can be completely customized upon request to satisfy your unique requirements.

Specifications

| LINE | PRODUCTION CAPACITY (Kg/h)* |

ENERGY CONSUMPTION (kWh/kg) |

|---|---|---|

| GM50 | 50-150 | 0.25-0.30 |

| GM65 | 150-260 | 0.25-0.30 |

| GM90 | 250-500 | 0.25-0.30 |

| GM105 | 400-680 | 0.25-0.30 |

| GM125 | 600-950 | 0.25-0.30 |

| GM160 | 1000-1400 | 0.25-0.30 |

| GM180 | 1500-2000 | 0.25-0.30 |

| GM210 | 2000-2800 | 0.25-0.30 |

*The capacity refers to LDPE, and can vary depending on the density of the material, degree of pollution, print and humidity percentage.

System Highlights

Cutter-Compactor

Add Value to Recycled Materials During Processing

The cutter-compactor presizes, heats, and compacts material before feeding into the extruder. It is the best and most flexible feeding solution for loose, low bulk density and high residual moisture materials. This solution can be fed with various devices, such as a conveyor belt, pneumatically, or a nip roll system for roll stock. It can be outfitted with several dosing systems for pellets, regrind, and powders.

Ecotronic® Control System

Ensuring Ultimate Precision and Energy Savings

The patented Ecotronic® control system enables precise temperature control without the use of water and can accept up to 12% residual surface moisture for various material streams. This solution guarantees up to 40% energy savings on the main motor.

Feeding Auger

Providing Consistent and Positive Feed

The feeding auger is one hallmark of our COMPAC technology. It is controlled by the amp load on the extruder and provides the most consistent and positive feed to the extruder. The feeding auger is especially useful for low bulk density materials and when material particle size is larger or not uniform.

Would you like more information on the

COMPAC System?

We’re here to help.

Fill out the form below and our team will contact you soon.