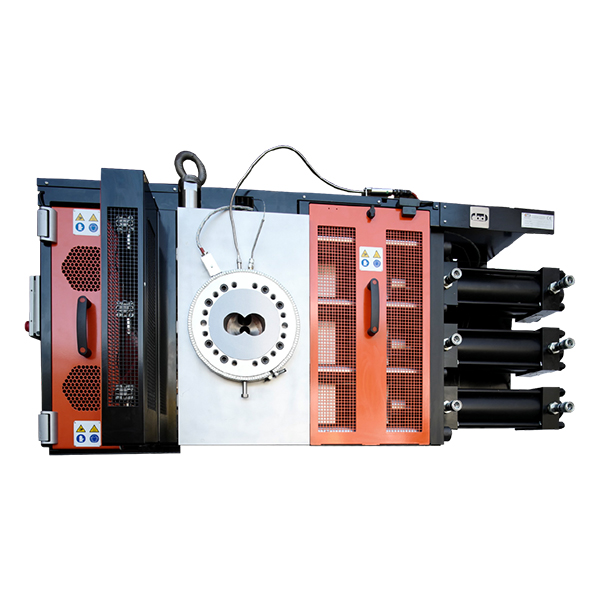

Hydraulic Screen Changers

MAXIMUM PRODUCTIVITY AND CUSTOMIZATION TO MEET THE MOST PARTICULAR NEEDS.

BD Plast offers different models of Hydraulic Screen Changers to meet the customers’ needs.

Main Advantages for You and Your Process:

- Compact design, ideal also in case of space limitation

- Independent movement of each slide plate, filtration area increased

- The only screen changer with automatic system for breaker plate ejection when screen replacement is needed

- No screen retaining devices needed

- Low backpressure needed (8 tested on process) for backflushing increased productivity

- High safety level through RFID microswitches implementation

- High efficiency backflushing cycle! Up to 200 cleaning cycles before filtration screens replacement

BDP manually operated hydraulic s/c is suitable for the processing of highly sensitive polymers due to the specific temperature control of each filter holder

Model BDO FT is characterized by simple design, ergonomics and rationality with which they were designed. Thanks to a uniform and efficient heating system, are suitable for the processing of highly sensitive polymers.

Model BDO FQ is designed for high production or recycling extrusion lines, due to ongoing technical development, have reached a high degree of ergonomics.

BDO x 2 dual plate hydraulic s/c is continuous screen changer able to avoid the shutdown of the system during the replacement of the filter elements with consequent savings of waste and unproductive time.

It allows very high working pressure levels. A simple and effective sealing system with interchangeable components allows even complex maintenance at customer site, minimizing downtime and costs.

BDOx3 BF backflushing hydraulic screen changer:

- The backflushing sequence is automatically managed by a PLC equipped with a Touch-screen panel, so the need of manpower is dramatically reduced.

- Through the implementation of a high efficiency screens cleaning cycle, we are ableto get nearly new cleaned screens with consequent cost reduction improvement.

- Customized trimming for the specific duty can be set during manufacturing but also on site through dedicated tuning devices.

- Breaker plates extraction is fully automated.

Would you like more information on Hydraulic Screen Changers?

We’re here to help.

Fill out the form below and our team will contact you soon.