THE CleanChanger®: CONTINUOUS FLOW SCREEN CHANGER

A PERFECT CONTINUITY OF THE POLYMER FLOW. ADVANCED TECHNOLOGY FOR WASTE REDUCTION IN THE PRODUCTION CYCLE.

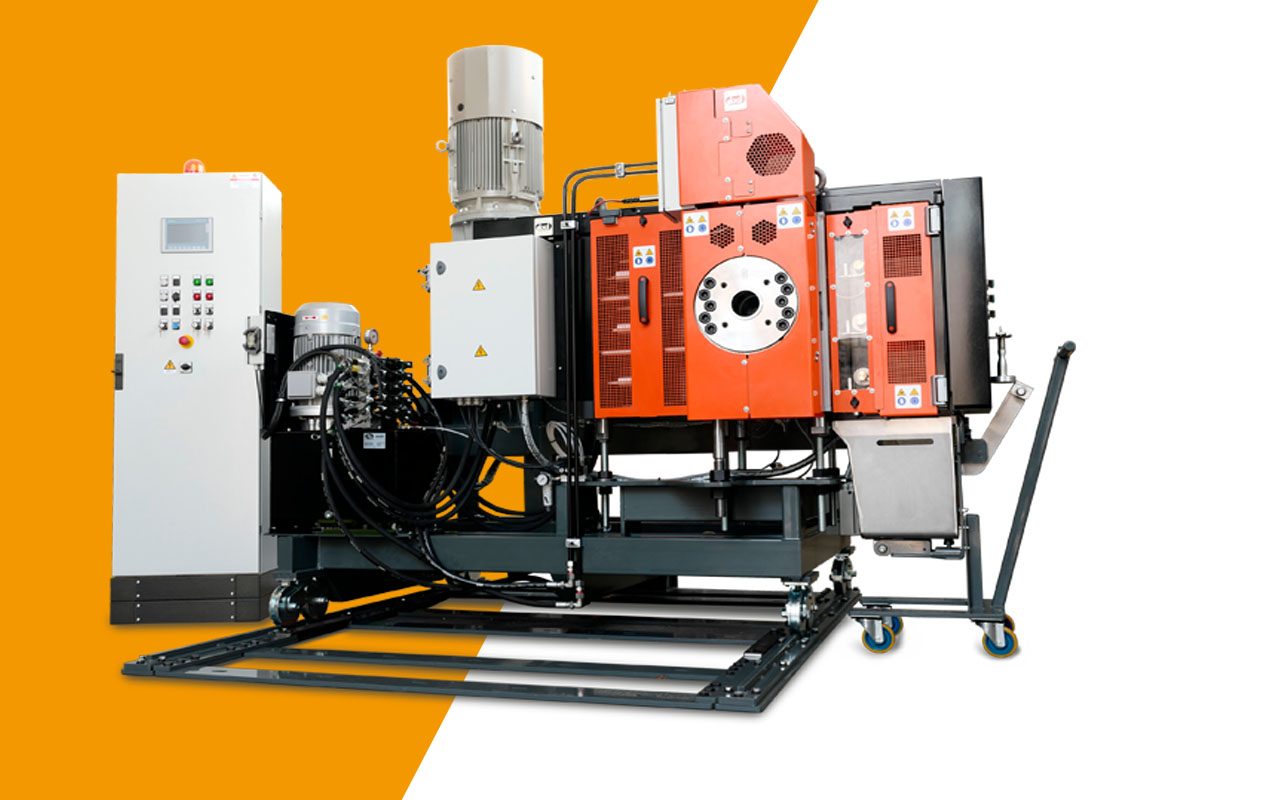

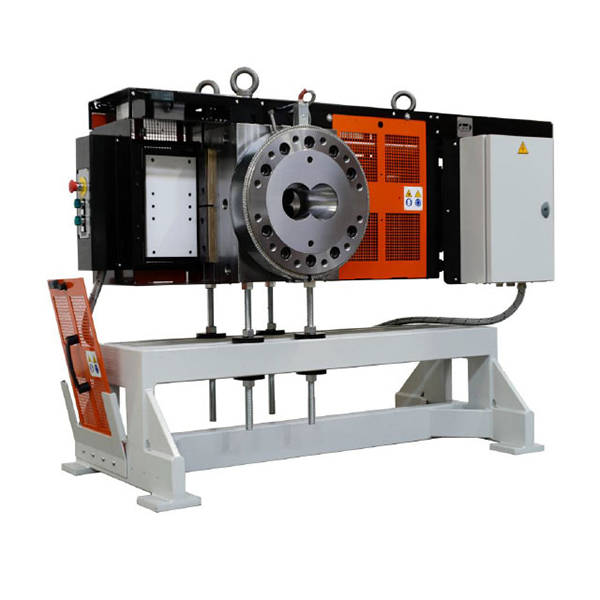

CleanChanger® is the automatic hydraulic, self-cleaning, triple plate screen changer with automatic ejection system of the breaker plates that allows for automatic filtration with independent movement of each plate.

SYSTEM HIGHLIGHTS

Thanks to its self-cleaning capacity at low backpressure, the automatic ejection of breaker plates, and its small purge time, the CleanChanger® is the only screen changer able to reach 300 self-cleaning cycles before the substitution of the screen packs.

The CleanChanger® is compact. The reduced dimensions facilitate its insertion inside installations. It is designed to fit naturally inside the filtering section and other system components (extruder, volumetric pump, diverter valve, strand dies and undercarriage support).

Robust insulation allows for less heat loss which equates to more energy savings.

CleanChanger® guarantees high-performance with maximum optimization of the flow channels, stability and continuity, excellent temperature control and an integrated process solution.

Thanks to BD Plast’s capabilities in engineering specific solutions fitting the customer’s needs, the CleanChanger® can be customized.

Would you like more information on CleanChanger®?

We’re here to help.

Fill out the form below and our team will contact you soon.