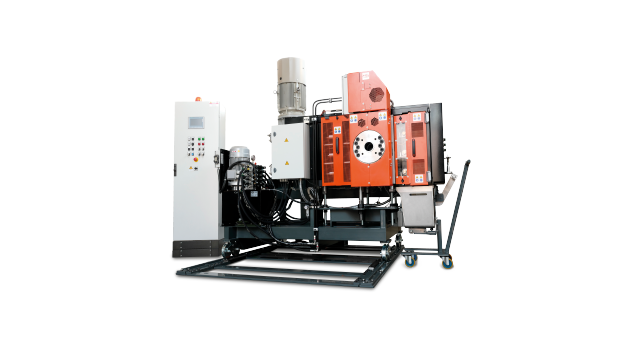

More Than Just

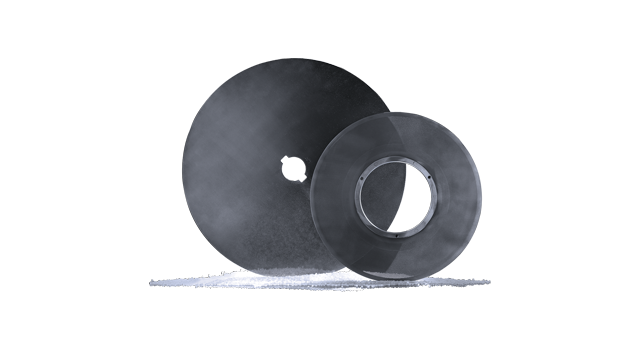

Recycling Machinery

Recycling Machinery

Committed to Sustainability For Our Environment and In Our Relationships

Not Just a Sales Agent

At Innovative Recycling Solutions, our number one priority is to help you find the best solutions to your problems.

That means acting as a consultant and helping you find the recycling machines that you actually need. We take the time to listen to your problems, get to know your business, and discuss the best way to satisfy your requirements. Our ultimate goal is to help people, even if that means sending business elsewhere.

Interested In Learning More?

If you have any questions or want to inquire for more information, we can start a conversation about what solutions will work best for you.