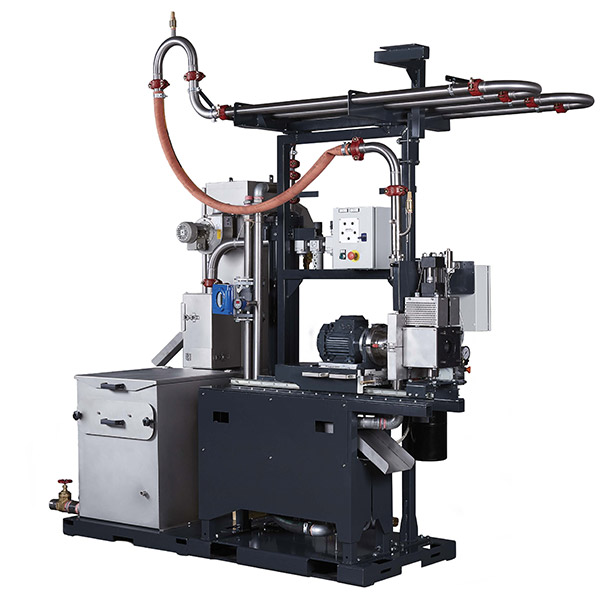

TDA Water Ring Pelletizer

Fast Start/Stop Sequence and Rapid Material Change

Pelletizing completes the recycling process. The pelletizing system (or die face cutter) is located at the very end of the line. The pelletizing phase gets its name because the recycled material is cut into small pellets and dried, appearing in a spherical or disc shape.

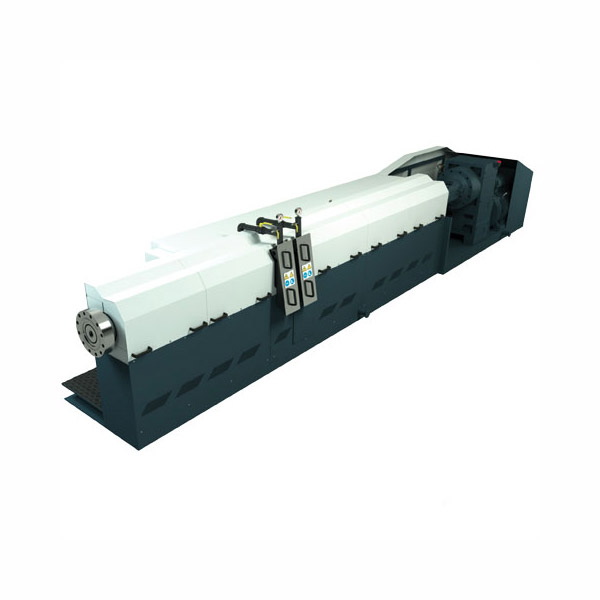

Gamma Meccanica’s TDA water ring pelletizer features an innovative design concept which allows for smoother and faster production starts and changeovers compared to former models. It can be installed on lines for average to large production capacities and is suitable for pelletizing almost all thermoplastics, including PE, PP, PS, ABS, MASTER, COMPOUNDING, and more.

Gamma Meccanica’s TDA water ring pelletizers are used in all of the complete systems and are also sold as standalone pelletizing solutions to other OEMs and end users’ extrusion lines. These pelletizers are compatible with all extruder models, regardless of the manufacturer.

Specifications

| TYPE | CAPACITY UP TO KG/H* |

|---|---|

| TDA 2.0 | 170 |

| TDA 4.0 | 700 |

| TDA 5.0 | 1400 |

| TDA 6.0 | 2500 |

*The maximum capacity refers to PE processing.

Key Advantages of Gamma Meccanica’s TDA Water Ring Pelletizers

- Compact System: pelletizing, cooling and drying occurs in the same unit

- Self-aligning spring loaded cutter head for better performance

- Simple to operate with minimal maintenance required

- Complete stainless steel construction

Would you like more information on

TDA Water Ring Pelletizers?

We’re here to help.

Fill out the form below and our team will contact you soon.